Understanding Plastic Testing: Ensuring Durability and Compliance

Understanding Plastic Testing: Ensuring Durability and Compliance

Blog Article

Plastic testing is a critical component in the manufacturing process that ensures the durability, safety, and regulatory compliance of plastic products. As plastics are used extensively in various industries, including automotive, healthcare, packaging, and consumer goods, rigorous testing is essential to ensure that these materials meet the required standards and perform reliably in their intended applications. In this comprehensive guide, we will delve into the importance of plastic testing, the various testing methods used, and how they contribute to ensuring the durability and compliance of plastic products.

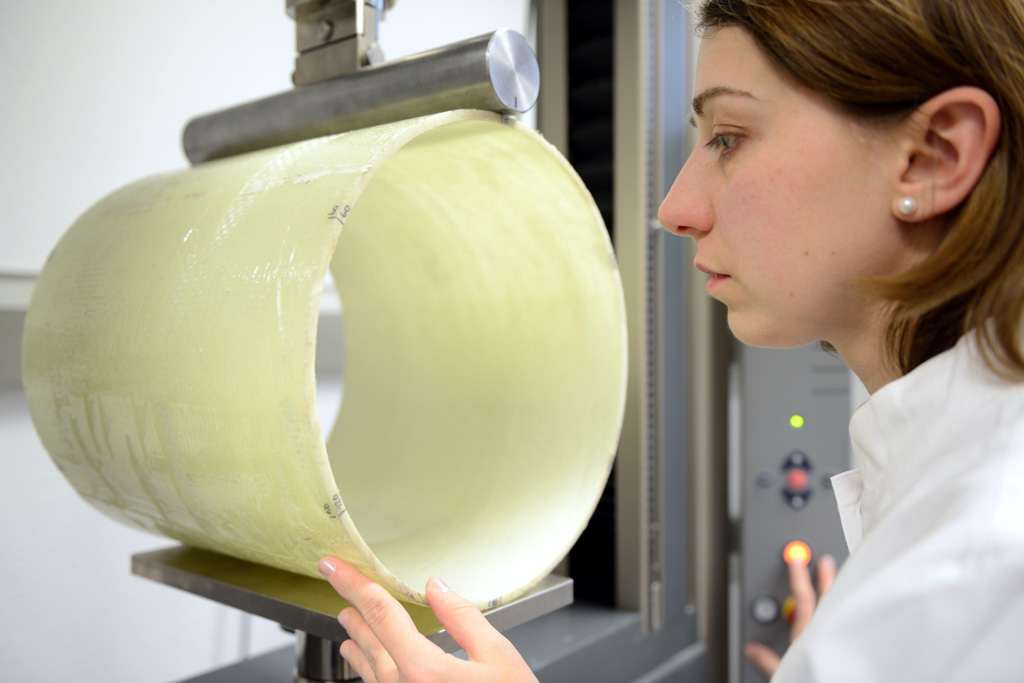

One of the primary reasons for plastic testing is to evaluate the mechanical properties of the material. Tensile testing, for example, measures the strength and elasticity of plastics by stretching a sample until it breaks. This test provides valuable data on the material's tensile strength, elongation, and modulus of elasticity, which are crucial for determining its suitability for various applications. For instance, packaging materials need to be flexible yet strong enough to protect their contents, while automotive components must withstand mechanical stresses without failing. Tensile testing ensures that the plastic materials used in these applications can endure the demands of their environments, providing manufacturers with confidence in their product's performance.

Impact resistance testing is another vital method used to assess the durability of plastic materials. This test evaluates a plastic's ability to absorb energy and resist fracture when subjected to sudden forces. Products such as helmets, automotive bumpers, and sporting goods often encounter impacts during use, making this test essential for ensuring their safety and reliability. By measuring the impact strength of plastics, manufacturers can ensure that their products provide adequate protection and do not easily break upon impact. For example, a helmet made from high-impact-resistant plastic can better protect users from head injuries, while an automotive bumper that absorbs impact energy can reduce damage to the vehicle and enhance passenger safety.

Thermal analysis is also crucial in plastic testing, encompassing techniques such as Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA). DSC measures the heat flow associated with transitions in plastic materials, such as melting, crystallization, and glass transition. This information is vital for understanding the thermal properties of plastics and their suitability for applications involving temperature variations. For instance, plastics used in electronic components must remain stable under high temperatures to prevent malfunction. TGA, on the other hand, assesses the weight changes in a plastic sample as it is heated, providing insights into the material's thermal stability and decomposition behavior. This is particularly important for applications where plastics are exposed to high temperatures, such as in the automotive and aerospace industries. Understanding how plastics behave under thermal stress helps manufacturers select appropriate materials that will maintain their integrity and performance in demanding environments.

Chemical analysis techniques, including Fourier Transform Infrared Spectroscopy (FTIR) and Gas Chromatography-Mass Spectrometry (GC-MS), play a crucial role in identifying the chemical composition and potential contaminants in plastic materials. FTIR provides a molecular fingerprint of a plastic sample, allowing for the identification of specific chemical bonds and functional groups. This information is essential for ensuring the purity of plastic materials and detecting any harmful additives or impurities. GC-MS, on the other hand, separates and identifies volatile compounds within a plastic sample, providing detailed information about its chemical makeup. These techniques are particularly important for applications where the chemical composition of plastics must be tightly controlled, such as in medical devices and food packaging. Ensuring that plastic materials meet chemical safety standards protects consumers from potential health risks and ensures compliance with regulatory requirements.

Environmental resistance testing is also crucial, assessing how plastics perform under exposure to various environmental factors such as UV light, moisture, and chemicals. UV exposure tests simulate the effects of sunlight on plastic materials, which is essential for outdoor applications where prolonged exposure can lead to degradation and loss of properties. For example, outdoor furniture, playground equipment, and agricultural films must withstand UV radiation to maintain their functionality and appearance over time. Moisture resistance testing evaluates how plastics absorb and react to water, which is critical for products used in humid or wet environments. This is particularly important for applications such as piping, containers, and marine equipment, where water exposure is inevitable. Chemical resistance testing determines how plastics withstand exposure to various chemicals, ensuring they do not degrade or lose their functionality when in contact with substances such as acids, bases, or solvents. This is essential for plastics used in chemical storage tanks, laboratory equipment, and household cleaning products.

Adherence to international standards is fundamental in plastic testing, ensuring consistency, reliability, and regulatory compliance. Organizations such as ASTM International and the International Organization for Standardization (ISO) provide guidelines and specifications for conducting plastic tests and evaluating results. ASTM standards, like ASTM D638 for tensile testing and ASTM D256 for impact resistance, provide detailed procedures for assessing the mechanical properties of plastics. ISO standards, such as ISO 527 for tensile properties and ISO 1133 for melt flow rate, are globally recognized and ensure that plastic materials meet high-quality benchmarks. Compliance with these standards not only ensures product quality and safety but also facilitates international trade by providing a common framework for evaluating plastic materials. Adhering to these standards helps manufacturers maintain product quality and regulatory compliance, ensuring their products meet the required benchmarks and perform reliably in their intended applications.

In addition to ensuring product quality and safety, plastic testing supports innovation within the plastics industry. By thoroughly understanding the properties and behavior of different plastic materials, researchers and engineers can develop new formulations with enhanced performance characteristics. This innovation supports the creation of high-performance materials for demanding applications such as aerospace, electronics, and renewable energy. For example, lightweight, high-strength plastics are increasingly used in aircraft components to improve fuel efficiency, while heat-resistant plastics are used in electronic devices to prevent overheating. Plastic testing also promotes sustainability by ensuring the quality and performance of bio-based and recycled plastics. Life Cycle Assessment (LCA) methods evaluate the environmental impact of plastic products throughout their lifecycle, helping manufacturers make informed decisions about material selection and product design. This comprehensive approach ensures that new and sustainable materials are reliable and effective for their intended uses, supporting the development of safer and more environmentally friendly plastic products.

Moreover, plastic testing is essential for ensuring compliance with regulatory requirements and avoiding costly product recalls. Manufacturers must adhere to various regulations and standards to ensure their products are safe for use and free from harmful substances. For example, the European Union's REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation requires manufacturers to identify and manage the risks associated with chemicals used in their products. Similarly, the U.S. Food and Drug Administration (FDA) has stringent requirements for materials used in medical devices and food packaging. By conducting thorough plastic testing, manufacturers can ensure their products meet these regulatory requirements, reducing the risk of non-compliance and the associated costs and reputational damage of product recalls.

Plastic testing also plays a crucial role in enhancing customer satisfaction and brand reputation. High-quality, safe, and reliable plastic products meet customer expectations and build trust in the brand. Consumers are more likely to purchase products from manufacturers known for their stringent quality control and adherence to safety standards. By investing in comprehensive plastic testing, manufacturers can differentiate themselves in the market, gain a competitive edge, and foster long-term customer loyalty. Additionally, the transparency and accountability demonstrated through rigorous testing practices can enhance a company's reputation, leading to increased market share and profitability.

Furthermore, plastic testing supports the development of innovative applications and technologies. As industries evolve and new technologies emerge, the demand for advanced plastic materials with specific properties continues to grow. For example, the rise of electric vehicles (EVs) has increased the need for lightweight, durable plastics that can improve energy efficiency and reduce vehicle weight. Similarly, the growth of renewable energy sources, such as wind and solar power, requires robust plastics that can withstand harsh environmental conditions. By leveraging advanced plastic testing techniques, manufacturers can develop cutting-edge materials that meet the unique requirements of these emerging applications, driving progress and sustainability across various industries.

In conclusion, plastic testing is essential for ensuring the durability, safety, and regulatory compliance of plastic products. Through various testing methods, including tensile testing, impact resistance testing, thermal analysis, chemical analysis, and environmental resistance testing, manufacturers can thoroughly evaluate plastic materials and identify any potential issues. Adhering to international standards, such as those set by ASTM and ISO, ensures consistency and reliability in testing procedures and results. Compliance with these standards not only meets regulatory requirements but also fosters innovation and sustainability within the plastics industry. As the demand for high-quality and sustainable plastic products continues to rise, the importance of rigorous plastic testing will only grow, supporting the development of safer and more environmentally friendly materials. Through comprehensive plastic testing, manufacturers can ensure their products meet the highest standards of quality and safety, ultimately benefiting consumers and the environment alike.

General FAQs:

What is plastic testing, and why is it important? Plastic testing involves a series of evaluations and analyses conducted on plastic materials to determine their properties, performance, and compliance with industry standards. This testing is crucial because plastics are widely used in various industries, such as automotive, healthcare, packaging, and consumer goods. Ensuring that these materials meet the required specifications and safety standards is essential for maintaining product quality, durability, and safety. By conducting thorough plastic testing, manufacturers can identify potential issues early in the production process, preventing product failures, recalls, and ensuring customer satisfaction.

What are the common methods used in plastic testing? Several methods are commonly used in plastic testing to evaluate different aspects of plastic materials. Tensile testing measures the mechanical properties, such as strength and elasticity, by stretching a plastic sample until it breaks. Impact resistance testing assesses a material's ability to absorb energy and resist fracture when subjected to sudden forces, which is crucial for products that might encounter impacts, like helmets and automotive parts. Thermal analysis, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), evaluates the thermal properties and stability of plastics. Chemical analysis techniques like Fourier Transform Infrared Spectroscopy (FTIR) and Gas Chromatography-Mass Spectrometry (GC-MS) identify the chemical composition and potential contaminants in plastics. Environmental resistance testing examines how plastics perform under exposure to factors like UV light, moisture, and chemicals.

How does plastic testing ensure regulatory compliance? Plastic testing plays a vital role in ensuring that plastic materials comply with regulatory requirements and industry standards. Organizations like ASTM International and the International Organization for Standardization (ISO) provide guidelines and specifications for conducting plastic tests and evaluating results. Compliance with these standards ensures that plastic materials meet quality benchmarks and regulatory requirements, facilitating international trade and consumer safety. For instance, the European Union's REACH regulation and the U.S. Food and Drug Administration (FDA) have stringent requirements for materials used in consumer products. By adhering to these standards and conducting rigorous plastic testing, manufacturers can avoid non-compliance issues, reduce the risk of product recalls, and protect their brand reputation.

What role does plastic testing play in product innovation and sustainability? Plastic testing is essential for product innovation and sustainability within the plastics industry. By thoroughly understanding the properties and behavior of different plastic materials, researchers and engineers can develop new formulations with enhanced performance characteristics. This innovation supports the creation of high-performance materials for demanding applications, such as aerospace, electronics, and renewable energy. Additionally, plastic testing promotes sustainability by ensuring the quality and performance of bio-based and recycled plastics. Life Cycle Assessment (LCA) methods evaluate the environmental impact of plastic products throughout their lifecycle, helping manufacturers make informed decisions about material selection and product design. This comprehensive approach supports the development of safer, more environmentally friendly plastic products.

How does plastic testing enhance customer satisfaction and brand reputation? Rigorous plastic testing ensures that products meet high standards of quality, safety, and performance, which is crucial for building customer trust and satisfaction. Consumers are more likely to purchase products from manufacturers known for their stringent quality control and adherence to safety standards. By investing in comprehensive plastic testing, manufacturers can differentiate themselves in the market, gain a competitive edge, and foster long-term customer loyalty. Additionally, transparency and accountability demonstrated through rigorous testing practices enhance a company's reputation, leading to increased market share and profitability. Ensuring that plastic materials meet all required specifications and standards ultimately benefits consumers and the environment, reinforcing the importance of plastic testing in today's market.